ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

Alain Besseyrias

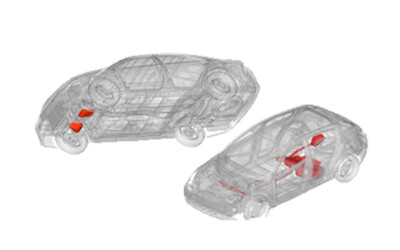

“When carmakers want to achieve a mirror finish, waviness is the most important characteristic,” notes Alain Besseyrias, manager of technical marketing for automotive at ArcelorMittal Europe – Flat Products.

“We need low waviness to achieve the best visual appearance for the part.

This helps to reflect light and create the highly polished finish associated with premium brands.”

Ing. Lubomír Roleček

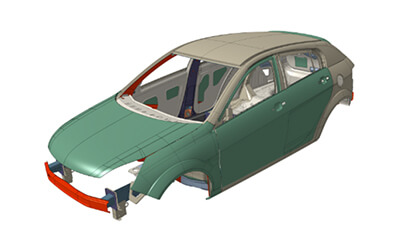

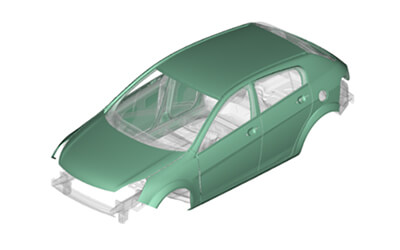

ŠKODA AUTO was closely involved in the early industrial trials of Ultragal® notes Ing. Lubomír Roleček, Manager of Skoda’s Technical Service Press Shop and Body Shop: “ŠKODA first achieved success with Ultragal® on the fender of our Octavia model and went into serial production in 2009.

Following this initial positive experience, ŠKODA AUTO decided to utilise Ultragal® on outer hood panels – a highly demanding application.

The aesthetics and excellent mirror finish of Ultragal® have now been applied to our Superb, Octavia, and Kodiaq models.

As you will see from the images in this article, the use of Ultragal® has real benefits when it comes to the final painted appearance of these parts.”

“Attractive aesthetics and a best-in-class paint finish are key requirements for our automotive customers,” says Paul Brettnacher, CMO for Automotive at ArcelorMittal Europe – Flat Products. “As a pioneer and leader in the production of hot dip galvanised steels with controlled waviness, ArcelorMittal is adopting the VDA Wsa1-5 norm to better serve our customers.”

“With our range of coatings for automotive, ArcelorMittal is making a key contribution to addressing the current challenges faced by paint shops,” says Paul Brettnacher. “Our sustainable and environmentally-friendly solutions lead to a reduced carbon footprint, and our advanced coatings answer customer requirements for better surface characteristics.”

Paul Brettnacher

To read the full article, please

Click here