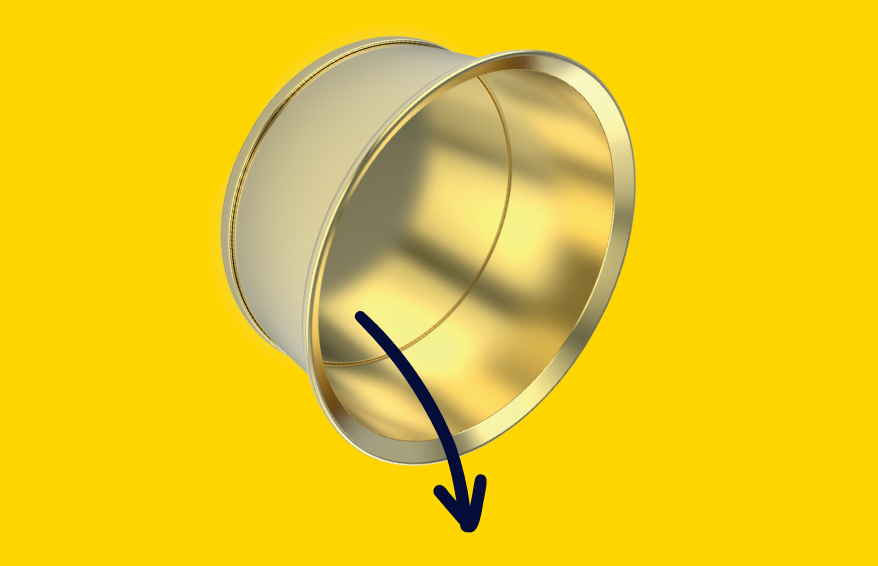

Ecopeel™'s design ensures the contents of the can are fully released.

The Ecopeel™ can from Eviosys has been created to improve the consumer experience while increasing the sustainability credentials of the packaging. With its peelable lid and a design that allows the can’s contents to be fully released, Ecopeel™ sets a new standard in sustainable packaging. The can body utilises TH480 packaging steel from ArcelorMittal Europe – Flat Products. Design support was provided by ArcelorMittal Global R&D who used Finite Element Analysis (FEA) to ensure that the can could be manufactured without any risk of critical material failure. The result is a unique can which provides a new consumer experience and a carbon footprint that is around 20-percent lower than comparable cans.

“Sustainability is a mandatory requirement in product development at Eviosys,” notes David Hall, R&D Director for Eviosys. “Our sustainability goal with the Ecopeel™ was to optimise the use of steel to package the same volume of food while achieving 100-percent product release.” Less material means emissions are avoided, while full product release ensures that all the food in a can is usable – avoiding food wastage.

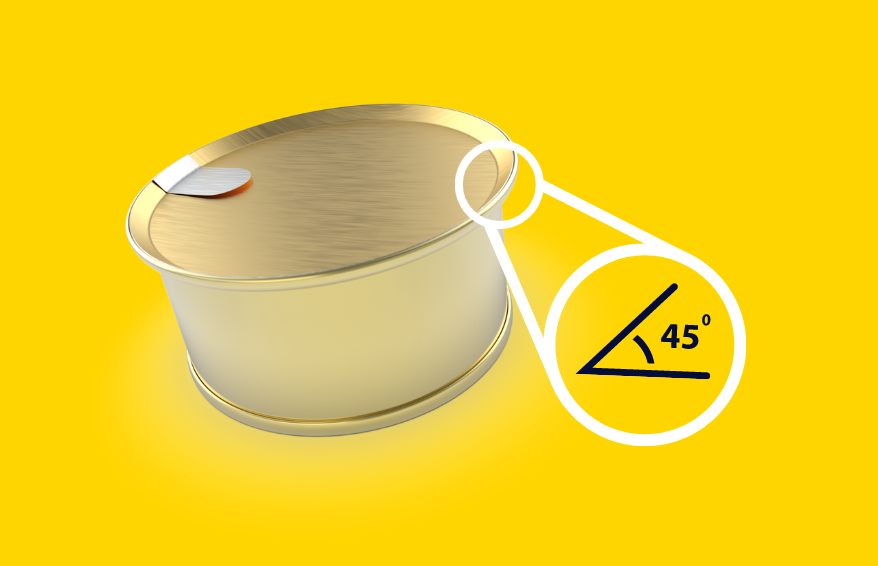

Eviosys achieved their goals by creating a cylinder with no ring. Instead, a 45-degree angle at the top edge is created which allows the peelable lid to be removed using minimal force. “The design provides a good combination of convenience, improved consumer experience, and a more sustainable packaging without compromising performance,” says David Hall.

ArcelorMittal’s Global R&D team became involved in the project in the final stages of the Ecopeel™'s development. Dr Lionel Gailliard, Packaging Product Development Manager for ArcelorMittal Europe – Flat Products explains: “After verifying the metal forming stages in their own facilities, Eviosys asked ArcelorMittal Global R&D to numerically check the feasibility of the Ecopeel™ body to ensure the body of the can would not break when the top was flared to accommodate the peelable seal. Using FEA and forming limit curves, ArcelorMittal Global R&D concluded that the part was fully feasible, even when taking the variability of the steel’s mechanical properties into account. This allowed Eviosys to confirm the steel specification and can design, without the need for costly and time-consuming trials.”

The Ecopeel™ was launched in Spain during the second half of 2023 where it is mainly used to package tuna. “There is a massive market in Spain for fish (particularly tuna) packaged in 85-gram portions,” explains David Hall. “While Spain and fish are the focus now, we have an ambition to roll out Ecopeel™ out to other countries, and to other types of contents. It is very suitable for solid products such as pet food and pate, and even dry food. The processable and scalable Ecopeel™ could also be used for ready meals, fruit, and vegetables.”

Feedback to the new Ecopeel™ can has been very positive from consumers. “End-customers appreciate the peelable lid which is very easy to remove,” says David Hall. “They also like the fact that the entire contents of the can come out when the lid is removed – there is no wastage.”

For fillers there is a very positive impact as David Hall explains: “The Ecopeel™ can is provided by Eviosys with the peelable seal in place. The can is filled from the bottom which is then seamed by the filler in the normal way. It is possible to fill cans five times quicker with less risk of contamination. This is vital for products containing fish and oil and much safer than heat sealing. For fillers very little investment is required to ensure their existing packaging lines are able to handle the new Ecopeel™.”

Giulia Marcaccio, Head of Marketing for Packaging at ArcelorMittal Europe, notes: “Ecopeel™ is a genuinely smart steel packaging innovation that fits well with ArcelorMittal’s core values to offer smarter (packaging) steels for people and planet. For people, Ecopeel™ brings convenience and easier use. For the planet, this unique steel innovation reduces the carbon footprint of packaging and increases awareness about food wastage. It will drive consumer demand for steel as their preferred packaging choice.”

TH480 is a standard steel for packaging which is widely used to package processed food in Europe. Using TH480 for the Ecopeel can enabled Eviosys to take full advantage of material standardisation.

When it comes to lightweighting, TH480 offers the material formability characteristics required to manufacture the Ecopeel™ in a very thin gauge. At the same time, TH480 offers a high level of performance which allows the Ecopeel™ to withstand the rigours of filling lines and the market distribution chain.

Using TH480 allowed Eviosys to enhance the substantial environmental benefits of the Ecopeel™ can by minimising the gauge of the body wall. The steel used in the can is easily extracted from waste streams using a magnet. The steel is fully recyclable over and over again without loss of properties.

Ecopeel™'s design ensures the contents of the can are fully released.

The 45 degree angle of the Ecopeel™'s lip makes it very easy to remove the peelable lid.

Read other customer success stories in the March 2024 edition of our client newsletter

Read other customer success stories in the March 2024 edition of our client newsletter