Over the past decade, the market for aerosol cans has grown by average of around seven percent annually. And demand for this attractive, convenient, and sustainable packaging format is expected to grow strongly in the future, largely led by consumer demand for personal care and household aerosol products.

ArcelorMittal Packaging Europe has made a strong commitment to support the aerosol market with the delivery of tailor-made steels for packaging. These products are used in a large range of aerosol can formats.

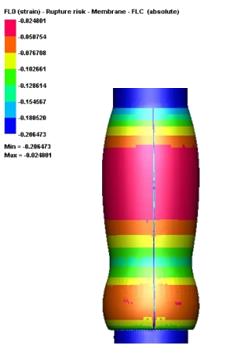

ArcelorMittal has also developed powerful numerical simulation tools which are helping canmakers to lightweight three-piece (3P) aerosols by optimising the geometry of their components. In sub-segments of the packaging market such as cosmetics, two-piece (2P) or monoblock aerosols may be the best solution. Here ArcelorMittal’s simulation tools enable us to define the optimised canmaking process to save weight and reduce canmaking costs. And where differentiation is a key marketing argument, the tools can help canmakers take advantage of the outstanding forming ability of steel to create eye-catching shapes.

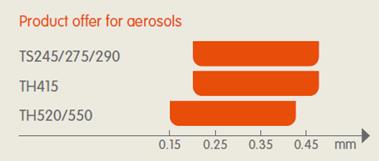

ArcelorMittal is a leading supplier of steel to aerosol canmakers across Europe. That is down to our extensive range of tailor-made steels for each component of the can. Our offer includes a large range of grades with:

Non-ageing grades with tight flatness and thickness control are also available. These are used to form the body of the aerosol.

ArcelorMittal’s product offer for packaging

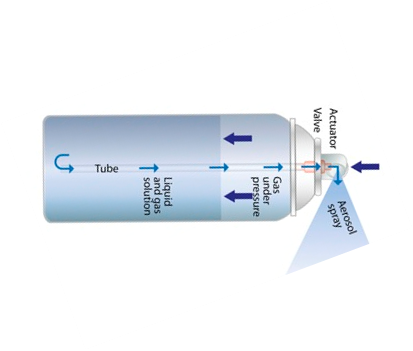

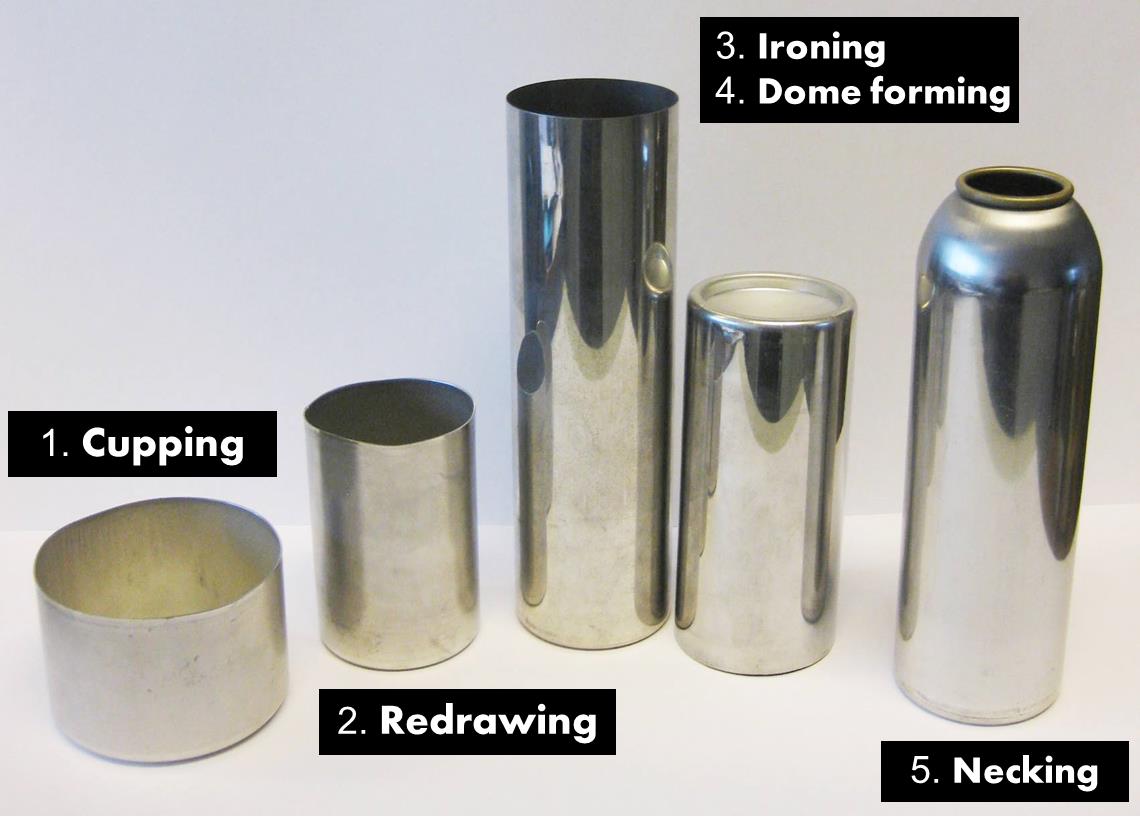

ArcelorMittal supports the development of next-generation ‘monoblock’ aerosol cans. This state-of-the-art design ensures welding and seams are not visible on the outside of the can. Mainly used for cosmetic products, monoblock cans result in clean and contemporary shapes which add to the prestige of a brand. Like 3P cans, they can also be shaped to create unique designs which differentiate products from their competition.

As well as helping the brand to stand out on the shelf, monoblock designs create a perception of high value in the mind of the consumer. Yet steel remains a very cost-effective solution for brand owners. Steel offers significant economic advantages – particularly for larger aerosol cans.

Example of a typical forming sequence for monoblock steel aerosol cans

Brand owners can exploit the shaping and embossing potential of steel to differentiate their products further on the market. Through our co-engineering approach, ArcelorMittal regularly helps canmakers to identify the correct grade and processes for each design.

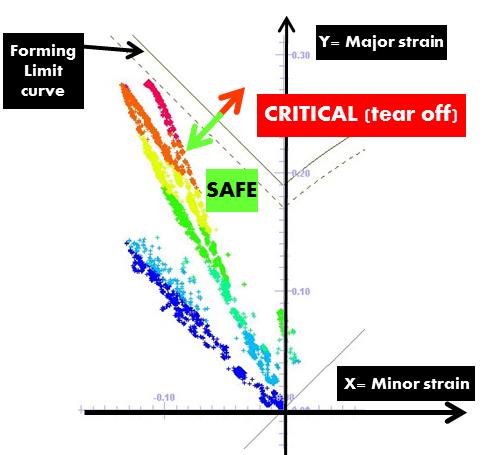

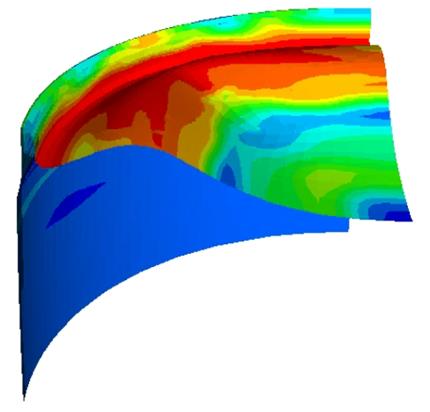

Safe formability assessment on a shaped 3P aerosol using numerical simulation

We can also offer technical assistance to canmakers who want to lightweight their cans or meet new regulations. ArcelorMittal’s support can include material selection and finite element modelling (FEM) to optimise the geometry of any component and adapt forming processes if necessary.

Tests can be carried out on physical samples (left) or using numerical simulation (right). This example shows the bottom of an aerosol can before and after buckling, and the same collapse using numerical simulation

One of the key reasons canmakers choose steel for aerosols is its excellent environmental performance. As permanent material, steel can be infinitely recycled without losing its properties. Steel packaging is also very easy to extract from waste streams with the use of a magnet. This ensures that the recycling rate for steel packaging is the highest of any material – 76 percent in 2014, the latest year for which data is available.

Steel offers significant advantages for canmakers when it comes to design flexibility, lightweighting, cost, and environmental performance. To find out more about ArcelorMittal’s packaging offer for aerosols, contact:

Pascal Amelot, Managing Director ArcelorMittal Flat products Packaging