Bonduelle sets ambitious sustainability target – and packaging steels play an important role

Bonduelle is one of the world’s leading producers of plant-based food. Canned products accounted for 46 percent of the company’s packaging materials by tonnage in 2018-19. Packaging materials are at the heart of Bonduelle’s approach to corporate social responsibility (CSR). The company has set itself the ambition of designing its packaging to be 100% recyclable or reusable by 2025. Achieving this goal requires new initiatives from packaging suppliers – and a change in consumer perceptions. And ArcelorMittal is up to the challenge.

One of the key challenges for Bonduelle is coping with the massive volume of fresh food it receives at the peak of the season. Preserving the harvest at the height of its freshness and taste requires solid, rigid packaging which is easy to handle and doesn’t damage easily. “Steel cans fit this process,” notes Arnaud Warusfel, packaging development manager for Bonduelle Europe Long Life. “For example, we need to sterilise a lot of cans in a very short time. Steel cans offer rapidity and strength at every step of the process. That ensures we can preserve the qualities of the vegetables and their freshness.”

After canning, the preserved food is stored until it is ordered by distributors or retailers. Then they are labelled to ensure information is localised, and then delivered. “The canned foods are stored at room temperature, so they no longer consume energy,” says Arnaud Warusfel. “And there is no need to expend energy chilling them during transport, on the shelf, or in the consumer’s home.”

25-percent weight reduction possible

With sustainability a key concern for consumers, Bonduelle has set ambitious targets to reduce the weight and thickness of the steel it uses in its cans. “We’ve been working with our can suppliers to reduce the weight of our metallic cans while maintaining the right performance for our processes,” explains Arnaud Warusfel.

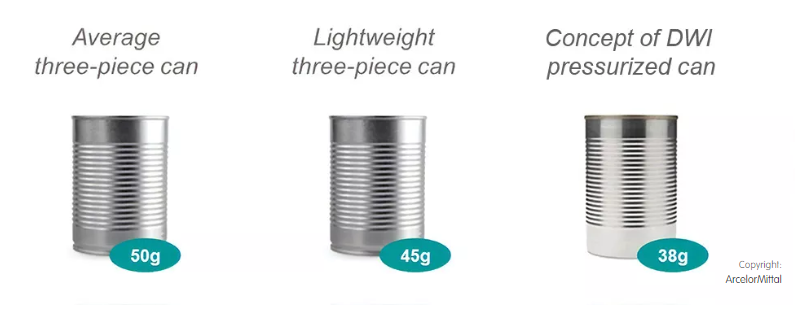

ArcelorMittal offers a range of thin-gauge high-strength steels for packaging which can withstand the rigours of the packaging process. “Using our packaging steels, an average three-piece vegetable can (diameter 73 mm, volume 425 ml) could be made 10-percent lighter, while the weight of pressurised DWI cans could be reduced by up to 25-percent compared to a standard can,” says Stéphane Tondo, CMO for packaging and electrical steels at ArcelorMittal Europe – Flat Products. “We continue to work closely with canmakers to develop even thinner grades.”

Getting the eco message to consumers

Despite their excellent eco-credentials, steel cans have a mixed perception amongst consumers as Arnaud Warusfel explains: “The metal can is seen differently in different countries. For example, Italian consumers have a positive perception of cans which they see as safe packaging. In other countries, cans are seen as old-fashioned and traditional packaging.”

A recent survey by Bonduelle in the Benelux found that only 35-percent of consumers understand that steel cans are endlessly recyclable. “Yet the recycling level of steel packaging in Europe reached 80.5 percent in 2017 according to figures issued by the Association of European Producers of Steel for Packaging (APEAL),” says Arnaud Warusfel. “In the Netherlands, they achieve a recycling rate of 96-percent, so we know there’s room for improvement in the rest of Europe.”

To get the message to its customers, Bonduelle has taken part in several education initiatives. For example, Bonduelle Europe Long Life decided to promote the endless recyclability of cans to consumers by including the ‘Metal recycles forever’ label on all their cans.

The benefits of increasing the recycling rate are immense notes Arnaud Warusfel: “Steel retains its mechanical properties and technical performance every time it is recycled. And as it is a ‘mono-material’ – only made from steel – steel cans are much simpler to sort in waste-treatment plants. That recycling makes it possible to limit the consumption of natural resources.”

ArcelorMittal is fully aware that this requires efforts from all stakeholders throughout the packaging lifecycle. “With canmakers and users we share responsibility for making the recycling of packaging steel a reality,” explains Stéphane Tondo. “For example, in France, ArcelorMittal’s Recycling Department manages the recovery and effective recycling of household steel packaging collected from homes and waste facilities thanks to contracts with municipalities.”

While there are still challenges ahead, Arnaud Warusfel recognises that steels for packaging are important: “Steel cans have a long shelf life, they are affordable, and they maintain the freshness of the vegetable throughout the year, not just at harvest time. They are a great solution for us, and our consumers.”

Copyright:

Image courtesy of Bonduelle

Related information

Why canmakers choose ArcelorMittal’s steels for packaging

ArcelorMittal is a local steel supplier with mills located close to the main food production regions in France, Italy, and Spain. This significantly limits emissions from transport. ArcelorMittal’s mills also meet Europe’s high environmental standards, ensuring the lowest level of emissions and the highest rates of recycling in the world.

ArcelorMittal can provide steel solutions for every part of the vegetable can. That includes three- and two-piece cans, standard and easy-open ends, and tabstock. These solutions enable producers to preserve food in a mono-material which is 100-percent recyclable.

Need steel? Find it on Steel advisor!

About Bonduelle

Bonduelle is a family-owned French company with 14,500 employees. The company’s plant-based ready-to-use food products are grown on 120,000 hectares and marketed in 100 countries. Bonduelle is the only brand present in all four segments of the plant-based food market: canned, frozen, fresh-cut ready to use, and fresh ready-to-eat prepared vegetables. The company’s main brands include Bonduelle, Cassegrain, Globus, Del Monte, Ready Pac Foods, Arctic Gardens.

More info: www.bonduelle.com