Florian Pick, Chief Sales Officer for ILAG [© ILAG]

Steel has been used by humans to cook food for centuries. Durable, safe, and 100-percent recyclable – it is the perfect way to cook delicious food. But one company – Guardini – wondered if steel could contribute even more to sustainable cooking. Then the Italian producer of bakeware for domestic cooks learnt about ArcelorMittal’s XCarb® green steel certificates. What followed was a three-year development process involving four partners across Europe. The result is XBake – a range of sustainable bakeware with a brand-new, non-stick coating that is free of per-and polyfluoroalkyl substances (PFAS). Launched in February 2023, XBake is the first consumer product to place the XCarb® branding onto the product packaging to spread awareness of its use of ArcelorMittal steel with XCarb® green steel certificates.

Guardini’s journey began when customers started asking about the level of recycled content in the company’s bakeware. Although Guardini actively recycles the unused steel from its processes, management realised it was impossible to quantify the level of recycled content in the new steel it purchased.

“XCarb® gave us the edge,” explains Marco Guardini, Managing Director of Guardini. “We could openly and reliably tell our customers that the steel was sustainably produced. Our calculations show that by using ArcelorMittal steel with XCarb® green steel certificates, we are reducing the CO2 impact of our products. That’s very significant and has attracted significant interest from our customers.”

XBake is the result of a four-way international partnership [© Guardini]

To prepare for potential PFAS restrictions in EU and the U.S. Guardini wanted to apply a non-stick coating which is PFAS-free to offer their customers a solution ahead of time. Both the European Union and the USA are taking steps to consider a ban of these PFAS chemicals in various consumer applications, including bakeware and cookware. Guardini turned to ILAG – a Swiss-based producer of coatings – to develop a completely new non-stick coating.

With almost 5,000 PFAS chemicals under review, ILAG were already researching PFAS-free solutions. Bakeware posed some unique challenges notes Florian Pick, Chief Sales Officer for ILAG: “Firstly, we needed to develop a new functional base for the non-stick coating which could withstand the pressing operations used to form the bakeware. Another challenge was getting the coating thickness correct on a high-speed coil coating line. In total it took us three years to develop the new coating.”

ILAG’s research team developed the new PFAS-free coating specifically for XBake [© ILAG]

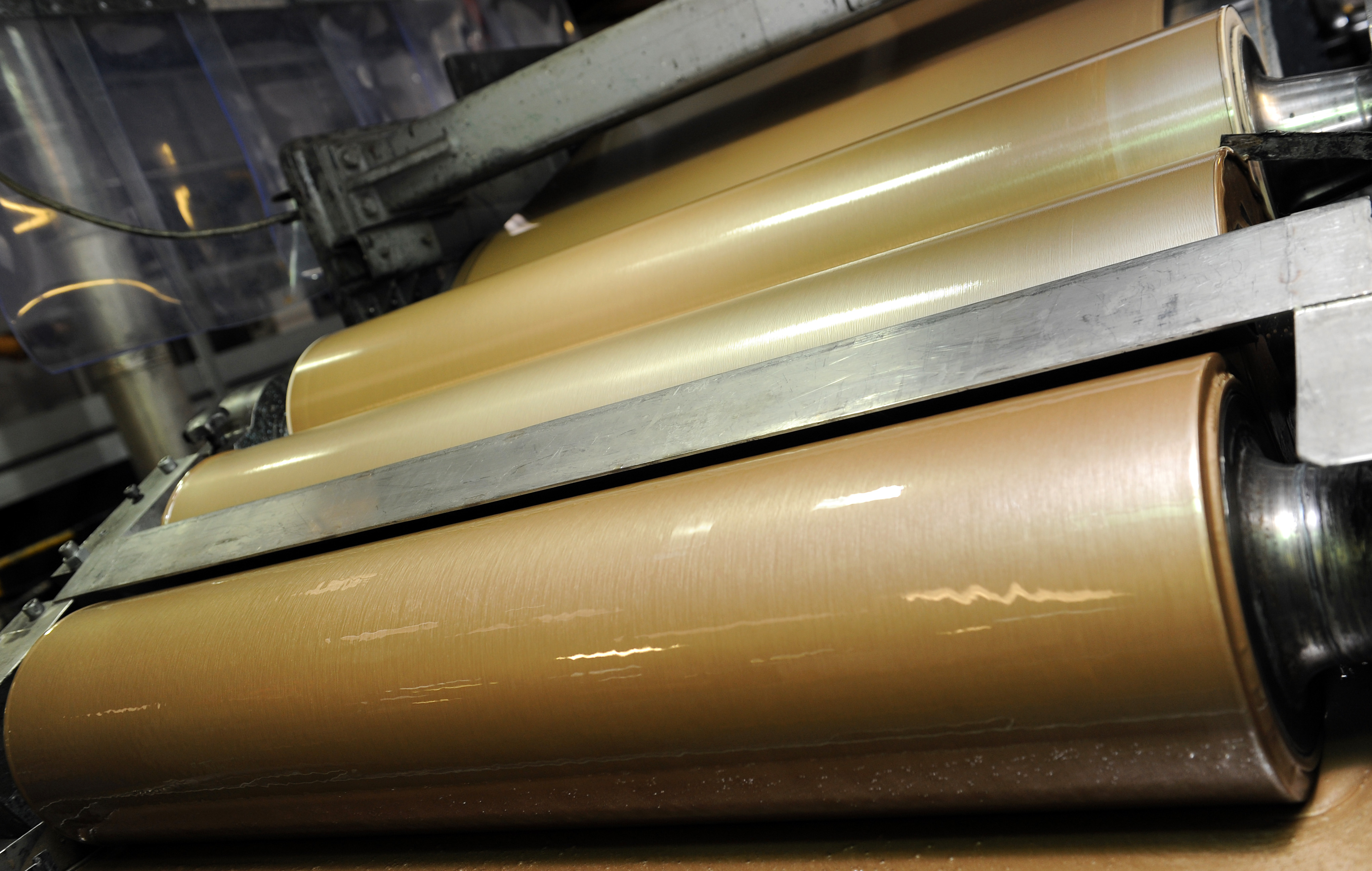

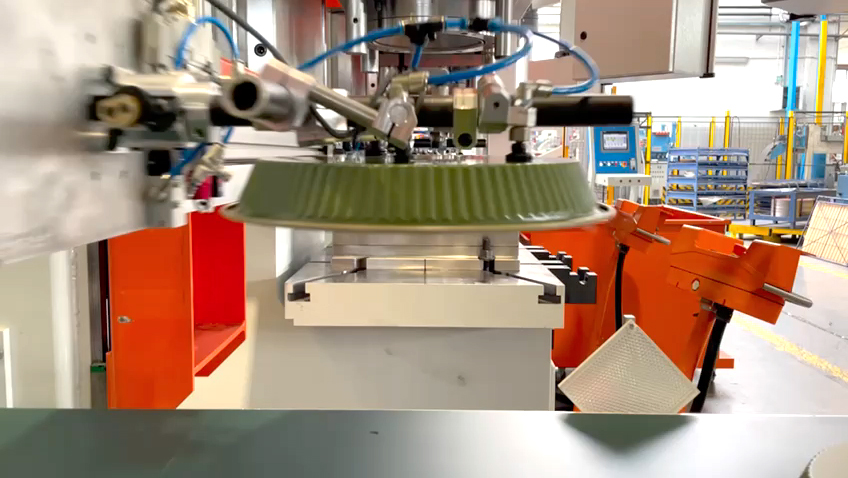

Testing and applying the new coating was the job of Cooper Coated Coil (CCC) – Guardini’s regular supplier of coated steels. “Guardini needs to be able to press the steel without affecting the coating,” says Kevin Tranter, Managing Director of CCC. “And we need to be able to apply it evenly to the coil at high speed. One of the first things we wanted to achieve was to establish the correct thermal conditions to ensure coating adhesion and performance during pressing. Today CCC is able to consistently produce commercial batches of this material on our high-speed coating lines.”

Today CCC buys the coils from ArcelorMittal with accompanying XCarb® green steel certificates. The coils are then coated with the PFAS-free non-stick coating before they are sold to Guardini. CCC pass the certificates to Guardini with the coil. “This enables us to account for and report a reduction in our Scope 3 emissions in accordance with the Greenhouse Gas Protocol Corporate Accounting and Reporting Standard,” says Marco Guardini.

Both sides of the steel can be coated. “The finished product looks glossier than non-stick PFAS coatings,” says Kevin Tranter. “In all other respects it performs as well as our other non-stick products.”

CCC applies the new coating on high-speed lines [© CCC]

The key to the success of the project has been the very close collaboration between the four companies involved. notes Marco Guardini: “Clear and fast feedback between ArcelorMittal, ILAG, CCC, and Guardini ensured the success of the project. Now XBake is available to home cooks around the world.”

Guardini now produces domestic bakeware using ArcelorMittal steel with XCarb® green steel certificates [© Guardini]

Marco Guardini, Managing Director of Guardini [© Guardini]

Guardini was founded in 1947 by Marco Guardini’s grandfather and his brother. The company initially made a variety of products for the house. In 1970s, Guardini started producing kitchenware before specialising in bakeware. Based in Volpiano, Italy, Guardini marked its first steps into sustainability with the construction of an energy efficient headquarters in 2014. The company employs around 100 people and exports its products within the EU and to markets in north Africa, eastern Europe, and north and south Americas.

More info: www.guardini.com

Kevin Tranter, Managing Director of CCC [© CCC]

CCC is a niche coil coating company specialising in the application of non-stick coatings to metal coils. They can paint metal strip with a range of speciality coatings, but specialise in products which use non-stick technology. Based in Wolverhampton (UK), CCC employs around 60 people and works with leading brands around the world.

More info: www.coopercoated.co.uk

Florian Pick, Chief Sales Officer for ILAG [© ILAG]

Established in 1955, ILAG has been producing non-stick coatings since the early 1980s. The company researches and develops coatings for consumer and industrial goods as well as domestic cookware. ILAG employs around 130 people at its headquarters in Switzerland and production facilities in China and Malaysia.

More info: www.ilag.ch

copyright: Banner image : Guardini