ArcelorMittal Packaging team keeps on delivering during European lockdown

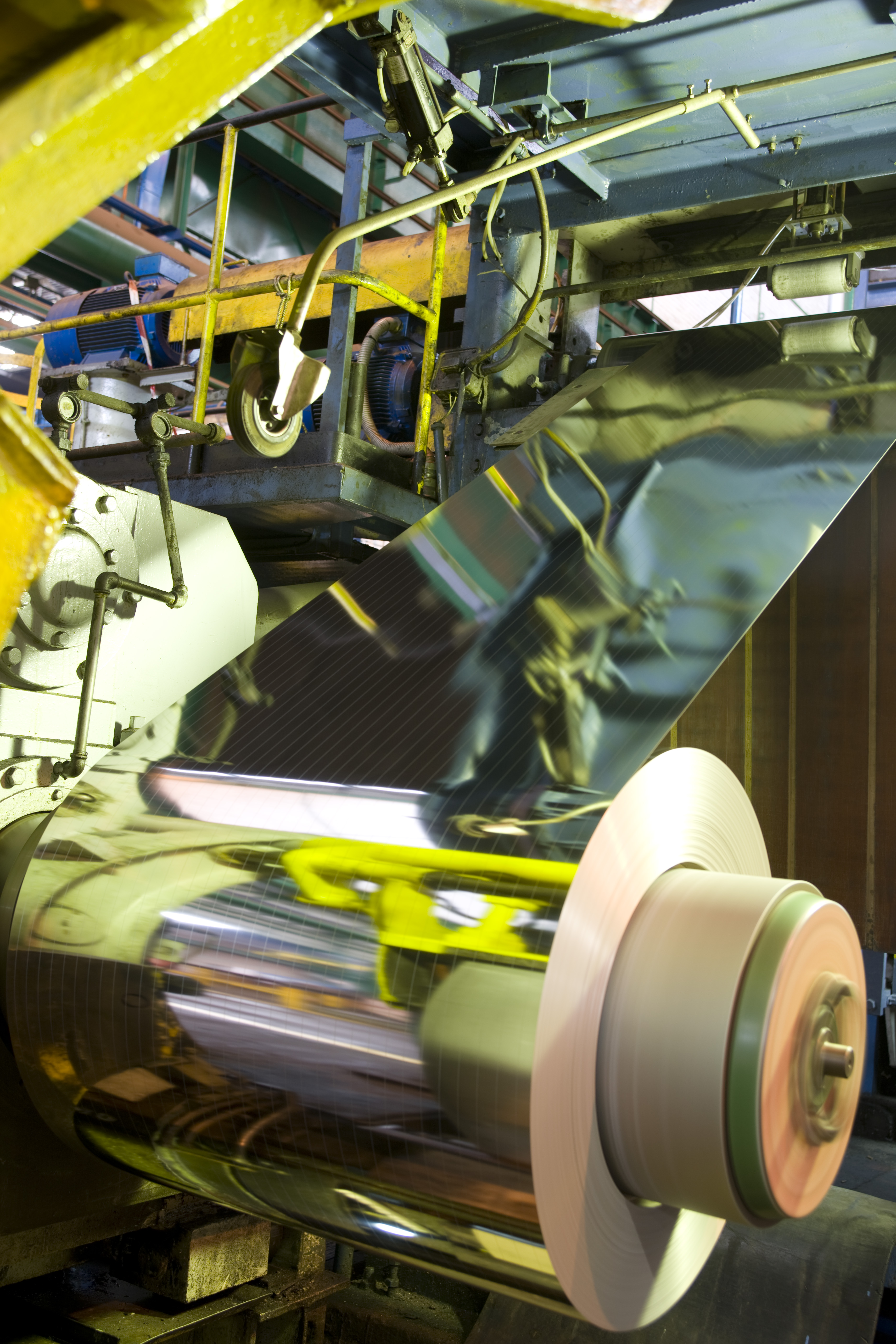

When the COVID-19 pandemic hit Europe at the beginning of 2020, consumers quickly became concerned about food supply chains. Many of them turned to canned food as a solution due to its long life, ease of use, nutritional value, and convenience. The unprecedented demand for cans posed significant challenges for canmakers and fillers at a time when government restrictions meant countries were in lockdown. To help them meet the challenge, ArcelorMittal immediately put a plan in place to step-up production of steels for packaging while protecting workers and customers.

The lockdowns implemented in Europe meant that there were significant disruptions to the food supply chain. At the same time, global demand for canned food reached unprecedented levels very quickly. That required an immediate response from canmakers, fillers, and steelmakers such as ArcelorMittal. “The long lead times and lack of flexibility offered by overseas producers were not an option, so most canmakers turned to local packaging steel suppliers such as ArcelorMittal,” says Stéphane Tondo, ArcelorMittal’s chief marketing officer (CMO) for packaging and electrical steels. “That meant ArcelorMittal’s mill teams had to quickly adjust our production lines so they could meet the demand.”

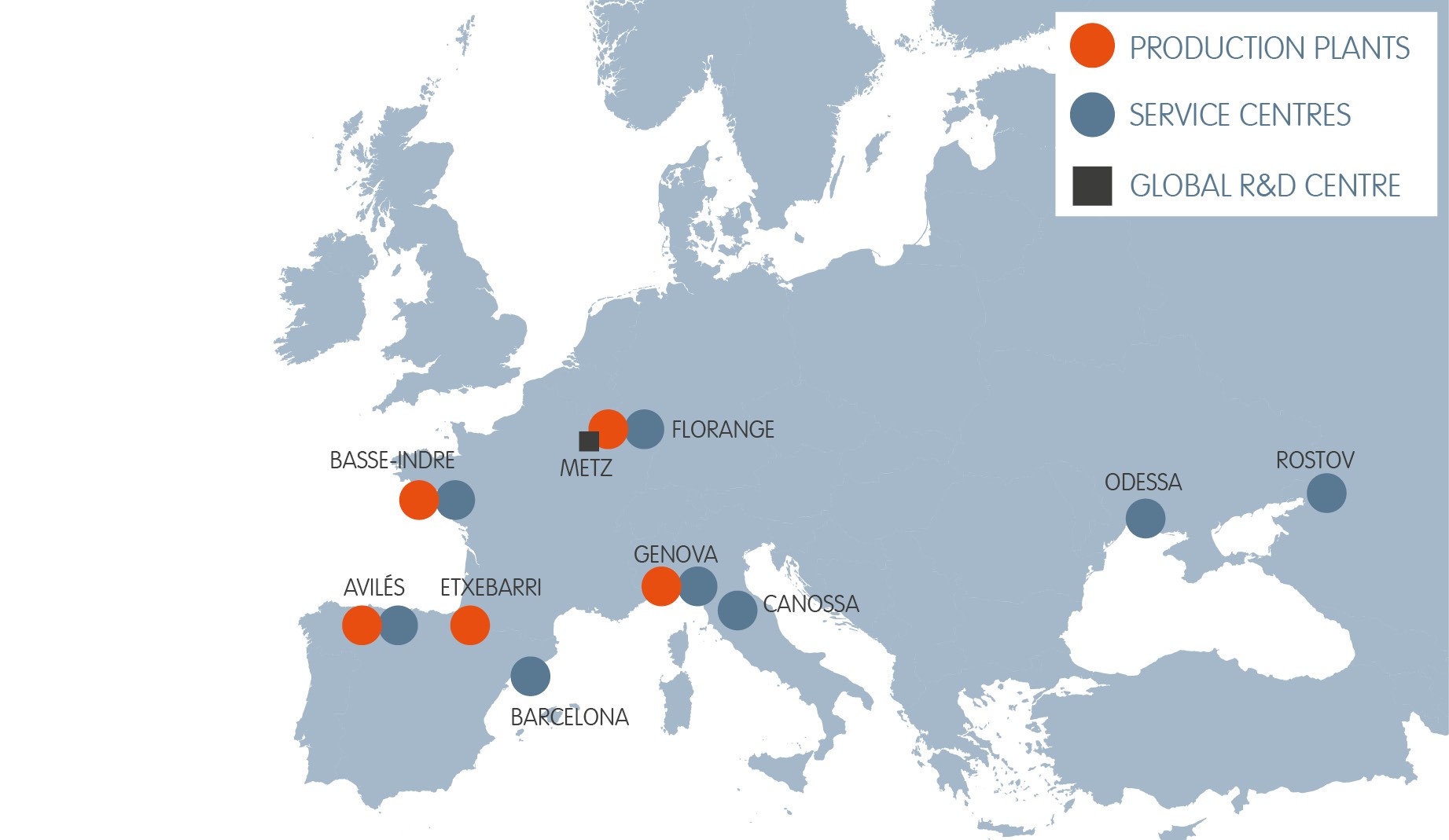

Proximity to customers provides flexibility

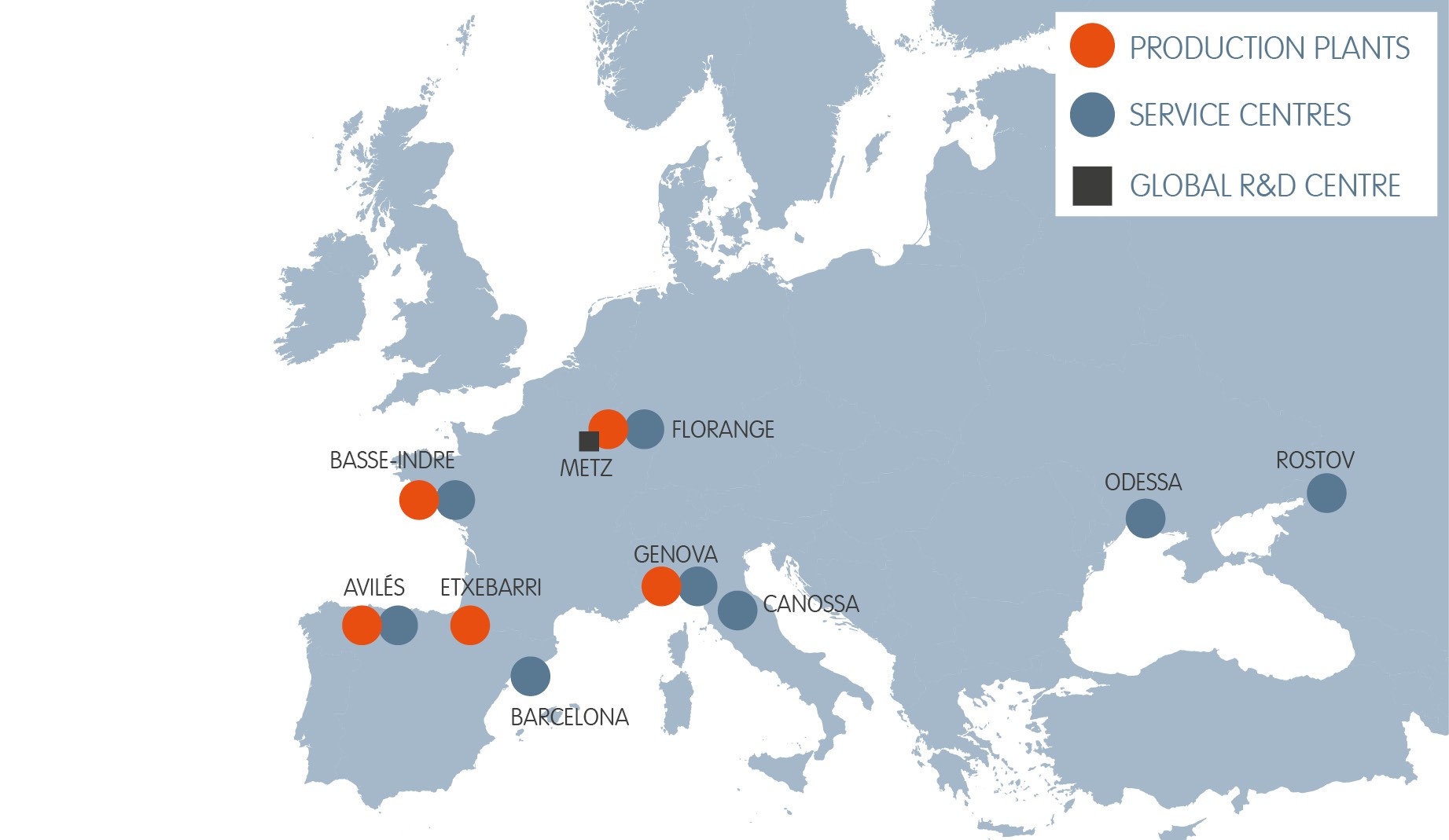

Thanks to its network of mills in France, Spain, Belgium, and Italy – ArcelorMittal was able to respond very fast while achieving a high level of flexibility for canmakers and fillers. Working from home, the Packaging sales team were in daily contact with their major customers and the mills to ensure the right material was available. “ArcelorMittal’s mills are already geographically close to major canned food producers which is a major advantage,” says Stéphane Tondo. “The mills are also able to back each other up, ensuring that we continued to produce the steels our customers needed.”

ArcelorMittal’s relationships with customers have been strengthened because of the crisis. “Our customers have been very loyal during the past few months and put their trust in ArcelorMittal,” says Stéphane Tondo. “We would like to thank them for their support and note that our flexibility and responsiveness will continue in the future – crisis or no crisis.”

Stéphane Tondo also recognises the extra efforts made by ArcelorMittal’s people: “ArcelorMittal’s Packaging team were very flexible and clearly understood the pressures that were on customers. The salespeople worked at full speed to make sure that communication with customers was clear. Their satisfaction was the main priority for everyone. And in the mills, our employees showed great commitment to ensuring we were producing quality steels safely.”

There was increased focus on sanitation at all stages of the supply chain notes Stéphane Tondo: “ArcelorMittal’s mills already have very stringent requirements with respect to the hygiene of packaging steels. But we also had to implement physical distancing measures and install extra handwashing facilities to keep our people safe and avoid product contamination. Gloves and masks were also quickly distributed to our staff.”

Rethinking the global supply chain

The COVID-19 crisis of 2020 will cause many canmakers and fillers to re-examine their supply chains and their service to customers. “ArcelorMittal’s local presence in Europe is a major advantage for these businesses,” says Stéphane Tondo. “Only a local supplier with the flexibility and presence of ArcelorMittal can offer the level of service customers require in a crisis such as this. We offered short lead times and late specifications, enabling customers to quickly respond in a rapidly evolving market situation. That is simply impossible with an overseas steel supplier.”

The crisis has focussed consumer attention on the food supply chain and helped them to rediscover canned food and its benefits. “Sales of food packaged in steel increased significantly,” notes Stéphane Tondo. “Tomatoes are a perfect example. Consumers discovered how versatile, nutritious, and tasty canned food is. We expect this trend to endure for the foreseeable future.”

Find out where we are in Europe

Copyright:

Image banner: STEKLO / shutterstock.com